If you’re a new blacksmith on a budget, then you probably just want to try forging the first piece of scrap metal you can find. But there are certain kinds of steel that you need to avoid, including galvanized steel.

Can blacksmiths work with galvanized steel? No! Galvanized steel is perhaps the biggest safety hazard that blacksmiths face. Working with galvanized steel can make you very sick and can even be fatal if you breathe in enough of the fumes. Galvanized steel is coated with zinc, which releases a toxic gas when heated. It can lead to a condition called metal fume fever. Trying to work with galvanized steel simply isn’t worth the risk.

In this article you’ll learn what galvanized steel is, how to identify it, whether blacksmiths can safely work with it, and how to safely remove zinc from galvanized steel.

Can Blacksmiths Forge Galvanized Steel?

Blacksmiths shouldn’t forge galvanized steel. Period. Not even if you’re working outdoors. Not even with a mask on. It’s simply too dangerous to take the risk with. There are plenty of courses of non-galvanized steel scrap out there and it’s not worth your time to try and remove the coating.

What Is Galvanized Steel?

Galvanizing is an action where a zinc coating gets applied to iron or steel. This is used to prevent the metal from rusting.

The most common way of galvanizing a piece of steel is to submerge it in a bath of molten hot zinc. This applies a thick protective layer of zinc to the steel.

How does a zinc coating prevent rust? The outer zinc coating corrodes first, leaving the steel or iron underneath untouched. Even if part of the zinc coating wears through, it can still protect the steel as long as there’s a solid contact electrically coupling the two metals together.

Galvanizing was first done to armor in the 17th Century to protect it from rusting.

Galvanizing can protect steel for decades before it will start to rust, but eventually the coating will fully break down. Being exposed to rain and other weather conditions can greatly shorten the life of a galvanized piece of steel. Galvanized steel used on seafaring ships also wears out quite fast, due to the combination of water and salt eating away at the coating.

Galvanized steel is used in everything from balconies, ladders, park benches, plumbing, and more.

How To Identify Galvanized Steel

Luckily, galvanized steel is usually quite easy to identify.

Most (but not all) galvanized steel has a surface pattern called “spangle.” This is a pattern created by the grain boundaries of the protective zinc coating.

Usually spangle looks like triangular shapes in the surface of the metal. Although some galvanized steel looks more like a camouflage pattern when you look at it up close. The pattern itself can be varied by manufacturers to create different aesthetic appearances by varying the cooling rate of the metal, as well as the size and number of zinc grains (called crystallites) used.

In some cases, the spangle pattern can be too fine to see with the naked eye. So while seeing a spangle pattern is a safe way to rule out galvanized pieces of steel that you don’t want to forge, a piece without spangle isn’t necessarily safe to use either.

How to find safe metal to forge

If a piece of steel is rusting, it’s usually safe for you to use as a blacksmith. One caveat I’ll include is that older pieces may have lead paint on them, so be careful when handling and removing any paint from steel.

If a piece of metal looks like it has been forged, you’re probably okay as well. But if it looks cast, it could be galvanized.

Old truck or car parts like leaf springs, coil springs, and axles are some of the safer pieces of scrap metal you can use. Usually they’re only coated with oil or possibly paint. Car axles are made of medium carbon steel, while springs are made of high carbon steel.

Sheet metal used in vehicle bodies can be good too, although on newer models some can be galvanized.

If needed, you can even melt down piles of nuts and bolts and weld them into a solid piece of stock.

Is galvanized steel magnetic?

Some people think that galvanized steel isn’t magnetic. This is wrong!

While zinc is non-magnetic and galvanized steel is coated in it, this doesn’t stop the steel inside from being magnetic. So don’t assume a piece of steel isn’t galvanized just because a magnet is attracted to it.

What does galvanized steel look like when heated?

Zinc gives off thick white smoke. If you see this while heating up your steel, stop immediately!

Burning zinc looks a bit like burning magnesium. It will burn super bright and white. The soot it creates is yellow, and the smoke can leave white oxide deposits on whatever it touches.

Why Isn’t Galvanized Steel Safe To Work With?

Zinc is an essential nutrient that the human body needs to survive. Normally we receive it in small amounts through the food we eat.

But you can get too much of a good thing. If you breathe zinc into your lungs, it’s absorbed much more easily and at levels far higher than what the body needs. This leads to overexposure and toxicity.

Heavy metal poisoning isn’t a joke. It will give you a nasty feeling hangover with lots of nausea and vomiting for days at best, or at worst it can cause serious lung damage or even death.

Most respirators aren’t equipped to deal with zinc fumes either, unless you’ve got one specifically designed to filter out heavy metals that uses a carbon filter.

Scrap steel is cheap and you can get it from a ton of different sources. So there’s not much excuse to take the chance and try to work with galvanized steel. Most of the steel underneath is low-grade stuff and won’t produce a great end product anyway.

It’s not just the metal you’re working forging!

If you’re making your own forge, be careful not to use galvanized steel when you make it either.

You might think that pipe fittings and other parts on your forge won’t get hot enough to vaporize zinc, but you’d be wrong.

I’ve heard of a few blacksmiths who used galvanized parts to build their homemade forge and quickly ended up with a sore throat that developed into flu-like symptoms. Most will recover and feel back to normal after a few days, but it’s still an unnecessary and terrible thing to put yourself through.

The moral of the story is: Never use galvanized steel to construct your forge or in anything else unless you’re 100% sure they won’t get too hot.

How To Safely Remove Galvanized Coating From Steel Or Iron

If you insist on working with galvanized steel or iron, you’ll want to remove the galvanized coating before you start working with it.

Burn it. If you live far out in the country where you’re away from other people, you can simply throw your pieces of galvanized steel into a big fire and walk away. That should burn off the galvanized coating. But don’t stand around and watch. If the wind changes without warning and you breathe in the zinc fumes, you could suddenly find yourself on your knees unable to breathe.

Sand it or grind it. You can sand or grind the galvanized coating off a piece of steel. Sanding is safer, since grinding will heat up the metal and may be hot enough to start releasing some fumes. Even the zinc particles could still irritate your lungs, so make sure to wear a respirator even while you’re sanding or grinding.

Soak it in acid. Vinegar will work, but it will need a while. You’ll want to soak your piece of galvanized steel for at least 24 hours if you’re using vinegar, but that should get most of the zinc off. A better and faster option is to get some muriatic acid from a hardware store and create a bath which will remove the zinc coating in 5 or 10 minutes. Again, this could still give off some pretty bad fumes, so do this outside in a well ventilated area and avoid breathing it in as much as you can.

Related Questions

Q: You must be exaggerating. This article just sounds like fear mongering. Have any blacksmiths actually died from working with galvanized steel?

A: Yes, look up Jim Paw-Paw Wilson for an example of a blacksmith who died as a result of zinc metal fume fever. Even experienced blacksmiths who think they know better can have a careless moment and get sick or die from working with galvanized steel.

Q: I heard drinking milk before smithing or welding can help avoid metal fume fever. Is that true?

A: No, it’s an old wives tale that cows milk can either treat or prevent metal fume fever. If you accidentally inhale zinc fumes, you’ll just have to wait it out. The traditional treatment is bed rest, taking aspirin for headaches, and staying well hydrated. In an especially bad case, you might need to go to the emergency room and get your lungs washed out.

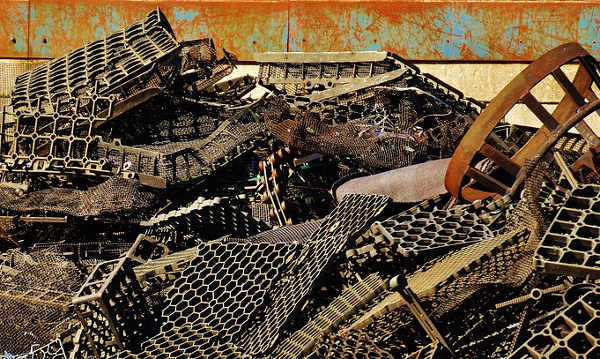

(Featured image by Andrew Beeston, used under Creative Commons)