Historically, the bellows was one of the most essential tools that a blacksmith had in his workshop. Without it, getting metal hot enough to bend and work with just wouldn’t have been possible.

What is the function of a blacksmith bellows? A blacksmith uses a bellows to deliver a constant supply of oxygen to the fire. This helps with the combustion process and allows for higher temperature fires. Hot enough to heat iron to the point that it can be molded and manipulated to create all sorts of objects.

Blacksmiths throughout the ages have used different methods to add extra air to their fire. In the earliest days, they would have had an apprentice use their lungs to blow on the fire. The bellows soon replaced the need for human lung-powered forges and was eventually replaced with hand-cranked fans and electric blowers.

In this article, I’ll explain what a bellows is, what it’s used for, the history of the blacksmith bellows, and finally what modern-day blacksmiths use to stoke their fires.

What Is A Bellows?

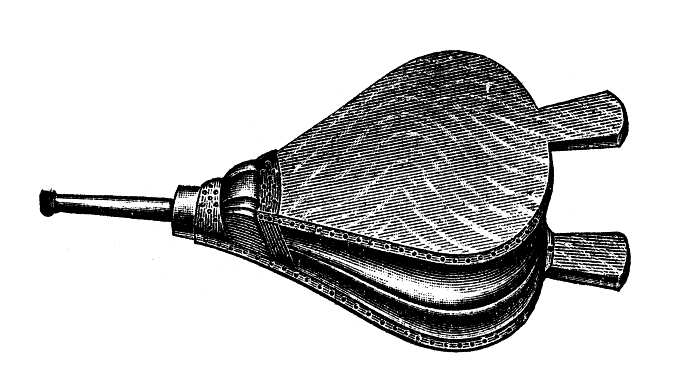

A bellows (also called a pair of bellows) is an object used to produce a strong gust of air.

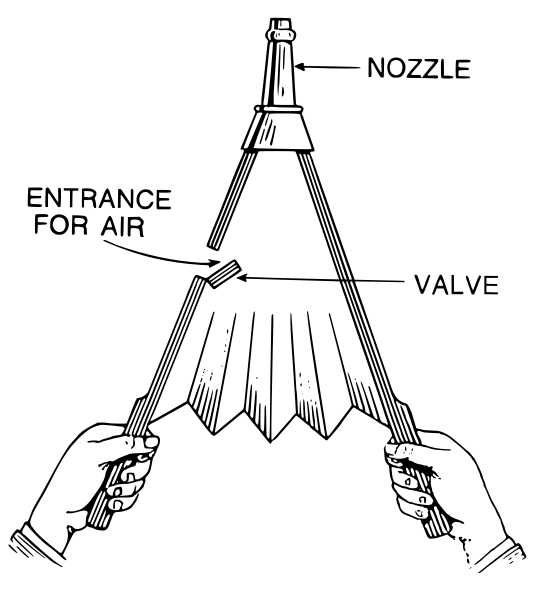

At it’s most basic, a bellows is just a flexible bag made out of two rigid boards that are connected with flexible leather sides. Inside is an airtight cavity that can be expanded and contracted by moving the handles of the boards in and out.

A bellows has a one-way valve that allows air to enter the cavity. It also has an outlet nozzle or tube at the front which allows pressurized air to be forcefully directed out in a stream when the bellow is squeezed.

A bellows has many applications. Did you know that even the accordion instrument uses a bellows to produce its music? But in this article, we are explicitly talking about the bellows that a blacksmith uses to supply extra air to a fire.

The word “bellows” comes from an Old English word meaning “blowing bag” or “blast bag.” Other old languages like Norse, Danish, and Swedish have similar words.

What Is A Bellows Used For?

If we think of the fire triangle, we know that a fire needs three things to continue burning: Oxygen, heat, and fuel.

A traditional blacksmith uses charcoal, coal, or coke as their fuel source.

They use a bellows to blow extra air onto his fire. That means more oxygen is available to burn. That makes the fire burn hotter than it would normally. Those hotter temperatures make it possible to make metal soft enough to shape with a hammer and is critical for the entire blacksmithing profession.

For that reason, smelting, blacksmithing, and welding were only made possible after the bellows had been invented for other purposes such as cooking.

In modern days, most blacksmiths have replaced their traditional bellows with motorized blowers and fans instead.

Different Types of Bellows

Blacksmiths use two main kinds of bellows: Double-acting piston bellows and two-chambered forge bellows.

When you think of a bellows, you probably imagine a two-chambered forge bellows. These are by far the most common and are quite similar to regular fireplace bellows. The main difference is that a fireplace bellows is more simple and only has one chamber.

Having two chambers means that a forge bellows can deliver a nearly constant stream of air and maintain very specific and steady temperatures.

Double-acting piston bellows are usually larger and stronger than a two-chambered forge bellows. They’re able to blow out air on both strokes of the handle, providing an even more constant flow of air.

Those two of the most common types of bellows that a traditional European blacksmith would have used. Although other countries have their own versions of bellows.

For example, in East Asia, box bellows were used. In Japan they used Tatara foot bellows. And the ancient Egyptians used pot bellows.

The History of Bellows

The Pre-Medieval Era

Before there were bellows, the only way that a blacksmith could create a fire hot enough to forge with was by getting their apprentice to blow through a long hollow tube onto the base of the fire.

As you can imagine, this wasn’t the most effective method. The apprentice could only do this heavy blowing for so long before they would start to get light-headed. So it was difficult to keep constant and steady.

Most blacksmith apprentices started their training before their 10th birthday. So it wasn’t like a grown man was stoking the fire, in many cases it was literally children.

On top of that, when they inhaled their lungs were absorbing most of the oxygen. Their exhalation was mostly carbon dioxide, which doesn’t help the fire.

It was a tough time both for blacksmiths and especially for their apprentices.

The Medival Era

Since having a child blow on your fire isn’t the most effective method, blacksmiths sought an alternative.

Medieval bellows were made of wood and leather. They directed air onto the base of a fire and allowed furnaces to reach temperatures high enough to melt iron.

Since they weren’t absorbing some of the oxygen like human lungs do, bellows were able to feed the fire with a lot more oxygen than a human could ever manage.

Instead of blowing on the fire directly, blacksmith apprentices now had the full-time job of operating bellows. While this is hours of repetitive, tedious and backbreaking work each day, it’s still an improvement over blowing on the fire until you get dizzy.

The bellows used in these times were made with two wooden paddles. In the middle of one of the paddles a hole would have been cut in the center. Inside the hole would have been a leather flap that only allowed air to flow one way. Air would rush into the bellows when the paddles were pulled apart, and expelled through a nozzle at the front when the paddles were pushed back together.

Hand-cranked Blowers

The traditional bellows began to be replaced by blacksmiths toward the end of the 19th century. They moved to adopting hand-cranked blowers made of cast iron. These blowers had fan blades inside their housing that used centrifugal force to push air out.

These blowers were more compact than a bellows. Nowadays they’re mostly just considered collectibles and antiques, as opposed to actually being used by professional blacksmiths.

Forge Blowers

Forge blowers are arguably one of the biggest quality-of-life improvements for blacksmiths and their apprentices, and one of the most important tools that a modern-day blacksmith has in their workshop.

These blowers are typically electric and can deliver a constant supply of air and oxygen to a blacksmith’s fire. Nowadays almost no blacksmiths use hand pump bellows or blowers because it’s just too much work.

Today’s forge blowers take up very little space and are much more convenient than any past fire-stoking technology. Plus they can be mounted out of the way. The speed can be adjusted to alter how much air is being fed into the fire.

Many beginner blacksmiths even get by using a hair dryer as a blower. This is still exponentially better than what pre-Medieval blacksmiths had access to!

Related Questions

Q: Do all blacksmiths use bellows or forge blowers?

A: No. Modern gas forges are able to maintain a temperature high enough to melt iron without the need for an external bellows or blower. They use built-in fans to maintain airflow. Only blacksmiths that use coal or coke forges need some kind of external blower.

Q: How come bellows don’t suck up hot air and catch fire?

A: Just like the one-way intake on the back of the bellows, the nozzle that air comes out is also one-way. This prevents hot air from the fire from being sucked back up inside of the bellows.

Conclusion

The way that blacksmiths stoke their fires has been constantly evolving. But for most of the history of blacksmithing, a bellows was the most efficient way to add extra air and oxygen to a fire.

The constant supply of extra oxygen of bellows helps to create higher temperatures. This makes it possible to heat iron until it can be bent and manipulated to create useful objects from.

Before the bellows was invented, a blacksmith had to rely on his young apprentice blowing through a hollow tube to increase the heat of his fire. The bellows was an improvement but has since been replaced.

Modern-day blacksmiths use electric forge blowers to provide an unrivaled level of control and steady airflow to their fires.

If you’re just getting started with blacksmithing, you probably won’t need a bellows. But check out my recommended gear page to see what equipment you’ll need to get started.

Bellows are pretty rare nowadays. Have you ever used one?